Introduction

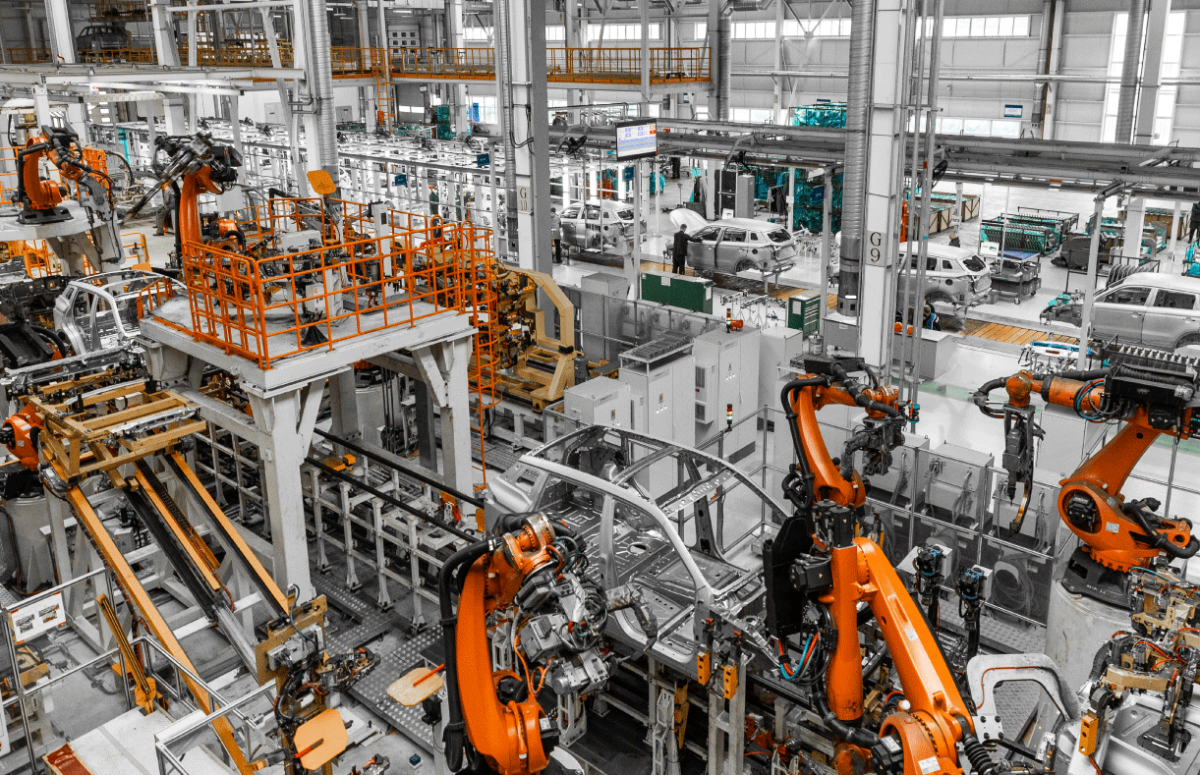

In the manufacturing industry, the three most common types of utilities are electricity, gas, and water. They are all fundamental requirements for organizations. Since automatic real-time data is not available in traditional industrial sector management strategies, each asset must be tracked and monitored manually, which takes a lot of time and effort. At this point, in order to avoid such challenges, asset management is crucial. It improves operations and offers a thorough understanding of the entire plant, which results in indirect energy savings. In this blog, we’ll talk about utilities and asset management and how important they are to manufacturing plants.

What is Utility Asset Management?

Manufacturing plants can manage and maintain crucial assets by using a utility asset management solution, which keeps track of lifespan, usage, maintenance history, and a variety of other factors. In order to support improved operational decisions, asset performance management (APM) improves asset management through data analytics, condition monitoring, and predictive maintenance. Equipment failure risk is reduced, and equipment life is maximized with a utility asset management system that has APM capabilities. Gained efficiency, lower emissions, and lower costs are the outcomes, along with optimal uptime and service reliability for end customers.

Utilities & Critical Asset Management solutions are crucial since the manufacturing sector depends substantially on the effective management of its industrial facilities and fixed assets. These solutions not only increase the dependability of machinery and equipment but also maximize asset utilization. This also helps organizations cut expenditures on asset-related maintenance and insurance by thousands of pounds.

What is a Utility Asset management plan?

An efficient asset management system includes utility asset management plans. They lay out the long-term plan and the actions required to appropriately and successfully manage assets over time. This covers a variety of things, such as the qualities and state of the assets, their service levels, scheduled maintenance, and much more.

It’s crucial for businesses to keep track of their assets since doing so can help them save time and money. A business must be able to frequently monitor and manage all of its assets and utilize them to generate the highest returns possible because it owns a variety of assets, including fixed and liquid assets.

Importance of Utility Asset management plan

According to the ISO 55000 series of asset management standards, asset management plans offer the road map for maximizing cost, risk, and performance throughout the asset lifespan in order to get benefit from physical assets. Utility asset management is crucial because it enables a business to systematically monitor and manage its assets. Plans for utility asset management ensure that assets are managed effectively and efficiently by outlining the complete lifecycle of each asset and allowing managers to monitor the overall performance of their assets. There are several advantages when managed properly.

Features of Utility Asset Management Solutions

In order for utility asset management plans to be successful, they must be backed by an asset management system, such as high-end asset management software.

Track all of your assets or resources

Utility asset management plans outline the assets’ locations, service levels, intended uses, and when and what modifications have been made. Asset recovery will result in greater returns, increased reliability, and regular compliance, according to data from a utility asset management software system, which can also assure accurate tracking.

Enhanced effectiveness in managing assets

Plans are made to be effective. Plans for utility asset management make it possible for all members of the organization to be aware of the capabilities and upkeep of the organization’s assets. In order to ensure that assets are being used efficiently, this involves the ability to track and evaluate the life cycle of the assets as well as a clear description of service levels.

Encourages collaboration with assets

For successful asset management, utility departments, locations, and manufacturing facilities must collaborate with one another. Additionally, by employing software for your management system, assets like trucks, tools, equipment, processes, and personnel may be efficiently handled from a single central location. This kind of internal cooperation boosts productivity and lowers expenses.

Lowers the cost of asset maintenance

Assets need maintenance just like tools and equipment do, and maintenance is a cost of doing business that may easily become excessive and reduce the company’s earnings. If you want to avoid overspending, employ an efficient utility asset management solution that makes sure that your utility asset management strategy specifies how frequently and when to undertake maintenance on specific assets.

Asset recovery

A utility asset management plan mandates planning for asset recovery and risk management in addition to the above advantages, allowing you to make sure your assets are appropriately managed and accounted for during their full life cycle. Each asset management strategy for utilities should include asset recovery. In reality, an asset management system automatically updates to reflect them. Asset recovery refers to the process of totally removing sold or scrapped assets from the company’s records and accounts. To free up storage space, related assets like consumables and spare components are disposed of or sold. A sound asset recovery procedure will guarantee that the business optimizes its profits without losing any property.

Risk Management

Plans for managing utility assets enable the adoption of a risk management strategy. This is particularly significant because maintaining assets also entails managing the risks associated with using those assets. When managing assets appropriately, reviewing the assets can help you spot potential dangers and develop a plan of action to assist you in order to avoid them.

Your utility asset management strategy will be complete and all-inclusive if it also addresses asset recovery and risk management. You can manage your assets effectively and run your business more efficiently if you have a utilities asset management plan. So, a business has to put a utilities asset management plan into place. Your utility asset management plan will act as a road map for your objectives with a long-term strategy and managerial involvement, allowing you to efficiently manage your assets for utilities.

Operational Challenges faced by Manufacturing Industry without a proper utility asset management system

The accessibility of utilities is no exception in a world of on-demand services and rapid access. Every manufacturing plant expects to have immediate, error-free access to water, gas, and electricity. Furthermore, there is no need for an alarm as long as utility procedures are functioning properly. However, when problems do arise and interfere with output, it has a significant effect. Disruption not only affects how paid consumers use services, but it also has an adverse effect on a company’s bottom line due to compensation and infrastructure maintenance.

For instance, from 2014 to 2018, gas and electricity utility suppliers of Europe paid out a staggering £29 million for falling short of promised service standards. The provision of utilities may face a number of difficulties, including: observing government laws and regulations that are continually changing, utilizing clean, renewable energy sources, modernizing deteriorating infrastructure, and incorporating AI and IoT into current workflows.

Although each of these problems hinders the development of utility services, one problem that shouldn’t be ignored is the administration and upkeep of assets. Pipelines, power stations, reservoir wells, power grids, dams, distribution and transmission lines, and the list goes on, are all vital assets for the power and utility sector. In addition, there are resources, infrastructure, information, and fleets. When a production-critical asset fails, service production also stops, which has an impact on total profits. So a proper utility asset management system is necessary to deal with such challenges.

Utility Asset Management Solutions: How do they benefit the Manufacturing Sector?

An asset management tool can assist in better managing and maintaining mission-critical equipment across whole operations when used by businesses and organizations that rely heavily on the use of their assets.

An AMS will offer organizations many advantages with many of its features and tools, including:

- Real-time monitoring of asset performance

- Creating maintenance programs that are preventative and proactive

- Monitoring the life cycle of an item from purchase through disposal

- Obtaining a precise ROI for every asset

- Accurately controlling inventories

- Organizing and monitoring field personnel

- Organizing and prioritizing work orders

The manufacturing industry can gain the following significant advantages from the utility asset management solutions:

Effective Audit and Inspection

Identification and verification of the organization’s assets depend heavily on auditing. How many and where are the assets that are rented? All of these questions have responses provided by the system. When determining taxation, the auditing component is also crucial. It can offer financial data for tax computation in accordance with the proper depreciation chosen. The program allows the business to track and monitor an asset’s location, condition, condition, etc., and do a rapid audit. Consequently, it simplifies compliance.

Optimized Inventory Management

The assembly line in production depends on its inventory. A manufacturing company may operate in multiple locations, geographically dispersed over the globe. The absence of a centralized system can cause activities to go wrong in such a situation. Because of a lack of coordination, there may be instances where incorrect information circulates, and work is improperly managed. Lack of goods in stock leads to lower productivity, missed deadlines for delivery, and business loss. If a machine breaks down and there are no spare parts on hand, the entire output could be impacted, which would result in losses. The use of utility asset management software centralizes business activities, ensures that accurate stock data is available, and prevents the dissemination of false information.

You can establish how many staff are spending how much time on each activity at work when you are tracking employee activity using the real-time location feature of the utility asset management solution. Work can be assigned to employees based on the current priority, such as the arrival of ad-hoc work. This improves the operations’ state of being a “work in progress.” This guarantees optimal worker performance and allocates personnel where they are genuinely required.

Unexpected breakdowns not only cost money but they also reduce an organization’s productivity. The utility or machine failure may result in the workers becoming idle. Regular maintenance prevents unplanned malfunctions, costly repairs, and the need to replace equipment parts. Preventive maintenance is where the utility asset management system places its emphasis. Since it is arranged in advance, it is often referred to as proactive and planned maintenance. This method is the most common and widespread maintenance activity practice in the manufacturing industry. The goal of preventative maintenance is to prevent a potential issue. The preventative maintenance software system assists in identifying any potential issues by using an information log.

When a utility or equipment is used for a severe workload, the value of maintenance is apparent. You receive frequent updates for an asset’s maintenance when you use asset tracking. Asset life tracking is also crucial for a company and is required. Using the utility asset management software, it is simple to determine whether an asset is functioning correctly, whether it requires any maintenance, etc. Overall, the system ensures that assets are operating efficiently and meeting objectives. When an organization’s assets are evaluated, it can make smart decisions that reduce expenses and increase the asset’s lifespan. The ability to track, manage, and extend an asset’s life cycle is one of the main advantages of asset management. Frequent updates and reports on asset maintenance are provided via asset tracking, where asset life is subsequently optimized.

The global positioning system (GPS), Bluetooth low energy (BLE), or the Internet of Things are used to tag assets within the utility. Although there are additional asset tracking solutions out there, the ones mentioned above are better at tracking assets in real-time. They are highly useful for the utility industry since they allow for the prediction of when assets will require monitoring and maintenance. The likelihood of equipment failure is lessened, and total maintenance costs are decreased when each of these technologies is employed. With these set tracking tags and software, utility assets are proactive, and tags keep the data organized. Also, the data can be used for analytics and to generate benefits and data-driven decisions. Furthermore, the management must make sure that the inventory is always on hand in the stock in order to execute maintenance tasks effectively. It has frequently been observed that the maintenance staff lacks inventory while performing maintenance, making this technique ineffective. Inventory alerts and notifies the appropriate party if it falls below a predetermined level, at which point the stock-filling procedure starts.

Tracks Asset patterns to Increase ROI

When tracking resources, a lot of data is gathered, and managers can utilize that data to uncover trends that will provide their company an advantage. Find out, for instance, which month has the highest and lowest utility demand based on the data. Utilize this information to develop a strategy that will help your organization flourish. Data is a strong tool that, when used correctly, can be incredibly advantageous. By keeping an eye on and tracking each asset from the time of acquisition until disposal, each asset can be maintained effectively. Also, predicting which asset should be abandoned becomes a difficult challenge when there are several assets! Asset tracking is necessary so that you can determine when an asset has to be disposed of. The utility asset management system notifies you when an asset needs to be disposed of. Furthermore, by keeping track of the cost of maintenance, you can figure out the return on investment (ROI). Utility management software can be used to accomplish all of these. Statista estimates that the global market for utility software was worth USD 4.2 billion in 2018. A CAGR of 3.5 percent was used to calculate the data for the period from 2019 to 2022.