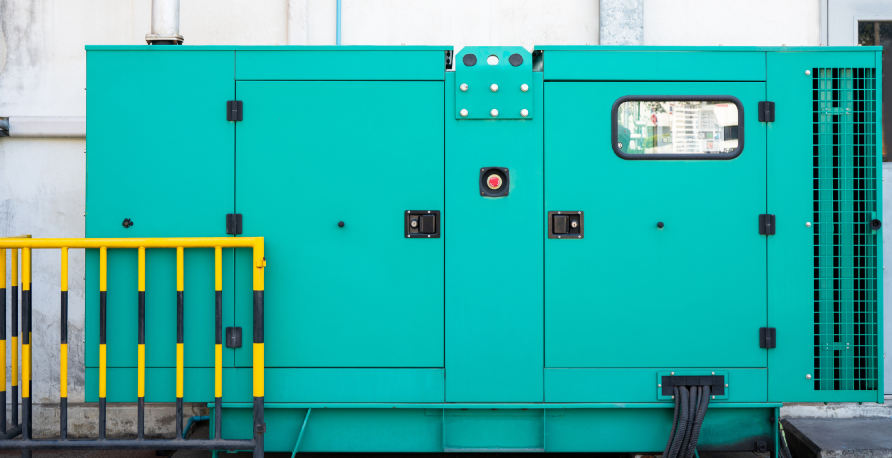

Introduction

In today’s fast-paced world, where uninterrupted power supply is a necessity for industries and establishments, diesel generators have emerged as critical backup power sources. To ensure their optimal performance and maintenance, diesel generator monitoring systems have become indispensable tools. This blog delves into the significance of diesel generator monitoring, shedding light on how it provides real-time insights that unlock improved performance and maintenance efficiency.

Diesel generator monitoring systems offer a wealth of benefits that contribute to enhanced performance and streamlined maintenance processes. With the ability to continuously track and analyze vital parameters such as fuel consumption, engine temperature, oil pressure, and load levels, these monitoring systems deliver real-time insights that empower operators and maintenance personnel.

Real-time insights are game-changers, as they grant operators the power of remote monitoring and control. Regardless of location or time, operators can effortlessly access critical information on the generator’s status, performance, and alarms. This instant visibility enables them to respond promptly to any deviations or emergencies, ensuring an uninterrupted power supply when it is most needed.

One of the most remarkable advantages of diesel generator monitoring lies in its predictive maintenance capabilities. By collecting and analyzing data in real time, these systems can detect trends and patterns that signify potential faults or deteriorating performance. Armed with this knowledge, maintenance can be scheduled proactively, mitigating the risk of unexpected breakdowns and optimizing maintenance costs.

Understanding Diesel Generator Monitoring

Diesel generator monitoring involves the continuous tracking and analysis of crucial parameters such as fuel consumption, engine temperature, oil pressure, and load levels. This monitoring process enables operators and maintenance personnel to remotely monitor and control generator performance, identify anomalies, and predict potential failures. Organizations can minimize downtime and operational costs by taking proactive measures and optimizing maintenance schedules.

Real-Time Insights for Enhanced Performance

Remote Monitoring and Control

Diesel generator monitoring systems provide real-time remote access, allowing operators to monitor critical information from anywhere, at any time. This remote access improves operational efficiency by providing instant visibility into the generator’s status, performance, and alarm notifications. Operators can monitor fuel levels, battery status, and load conditions, enabling timely responses to any deviations or emergencies.

Predictive Maintenance and Fault Detection

One of the significant advantages of diesel generator monitoring is its ability to enable predictive maintenance. By continuously collecting and analysing data, monitoring systems can identify trends and patterns that indicate potential faults or deteriorating performance. Predictive maintenance helps schedule maintenance tasks before failures occur, reducing the risk of unexpected breakdowns and optimizing maintenance costs.

Optimal Performance Optimization

Monitoring systems provide valuable insights into the generator’s performance metrics, such as fuel consumption, efficiency, and emissions. By analysing this data, operators can identify areas for improvement, optimize fuel usage, and enhance overall generator performance. Fine-tuning the generator based on real-time insights leads to improved efficiency and reduced operational expenses.

Key Components of Diesel Generator Monitoring Systems

Sensors and Data Collection

The monitoring system relies on sensors strategically placed on the generator to collect relevant data. These sensors capture parameters such as fuel levels, temperature, pressure, and load information. The accuracy and reliability of the collected data are crucial for effective monitoring and analysis.

Data Transmission and Storage

To ensure real-time monitoring, the collected data needs to be transmitted securely to a central monitoring system. This transmission can be achieved through wired or wireless communication channels. Additionally, robust data storage systems are necessary to securely store and archive the data for future analysis.

Data Analysis and Visualization

The collected data undergoes analysis using advanced algorithms and analytics tools. Data visualization techniques, such as graphs, charts, and dashboards, enable operators and maintenance personnel to interpret the data easily. Visual representations help in identifying trends, patterns, and anomalies, facilitating informed decision-making.

Implementing a Diesel Generator Monitoring System

Selecting the Right Monitoring System

When implementing a diesel generator monitoring system, it is crucial to choose the right solution that meets the specific requirements of the organization. Consider factors such as the size of the generator fleet, desired monitoring capabilities, scalability, and integration with existing systems. It is also essential to select a system that offers compatibility with different generator models and manufacturers.

Installation and Configuration

Once the monitoring system is selected, it needs to be installed and configured properly. This process may involve installing sensors on the generator, connecting the monitoring system to the generator’s control panel, and setting up communication channels for data transmission. It is important to follow manufacturer guidelines and ensure that the installation is performed by qualified technicians.

Training and Integration

To maximise the benefits of the diesel generator monitoring system, proper training and integration are essential. Operators and maintenance personnel should receive training on using the monitoring system, interpreting the collected data, and taking appropriate actions based on the insights provided. Integration with existing maintenance management systems or software can streamline workflows and enhance overall efficiency.

Overcoming Challenges and Maximizing Benefits

Implementing a diesel generator monitoring system may present some challenges, such as initial investment costs, system compatibility, and data security concerns. However, the benefits outweigh these challenges. By leveraging real-time insights, organizations can optimize generator performance, reduce maintenance costs, and minimise downtime. Regular system updates, data backups, and robust security measures can address concerns and ensure the system’s effectiveness.